Ball valves|Hydraulic accumulators|Pumps|Hydraulic cylinders|Filters|Filter elements|Hydraulic units

Welcome to Herzog Hydraulik GmbH

Our company has been established as a successful supplier of industrial hydraulics products in the global market since more than15 years.

With our wide range of products from well-known manufacturers such as Bosch-Rexroth, Hydac, Siemens, Eaton-Vickers, Parker, Internormen, Orsta and many more, we offer end users and resellers the opportunity to order quickly and easily obtain a wide variety of products from one place. As the hydraulic products are delivered directly from the manufacturer’s factory to our warehouse, we can guaranteeing high quality standards and short delivery times.

We are particularly competitive in the production of customized cylinders, as well as filter elements, which are manufactured according to your individual requirements.

Due to modern working schemes in customer service and versatile qualification of our specialists we are at your side as a competent partner – high quality is our priority.

The Herzog Hydraulik Team is looking forward to hearing from you !

Service and repair of hydraulic and pneumatic systems.

Our team has many years of experience in servicing and repairing of hydraulic and pneumatic systems. The repairs, for which only original spare parts are used, are carried out in specialized factories in Germany. This guarantees a high standard of quality.

Our service includes:

- Hydraulic pumps and motors for road construction technology and production

- Hydraulic cylinders of various designs and sizes

- Hydraulic accumulators: safety checks with issuance of the corresponding certificates

- directional valves

- Compilation and delivery of spare parts for any hydraulic equipment

- Advice on equipment selection, project planning and preparation of sketches/drawings, as well as requirement lists

Products

Customized industrial hydraulics and pneumatics

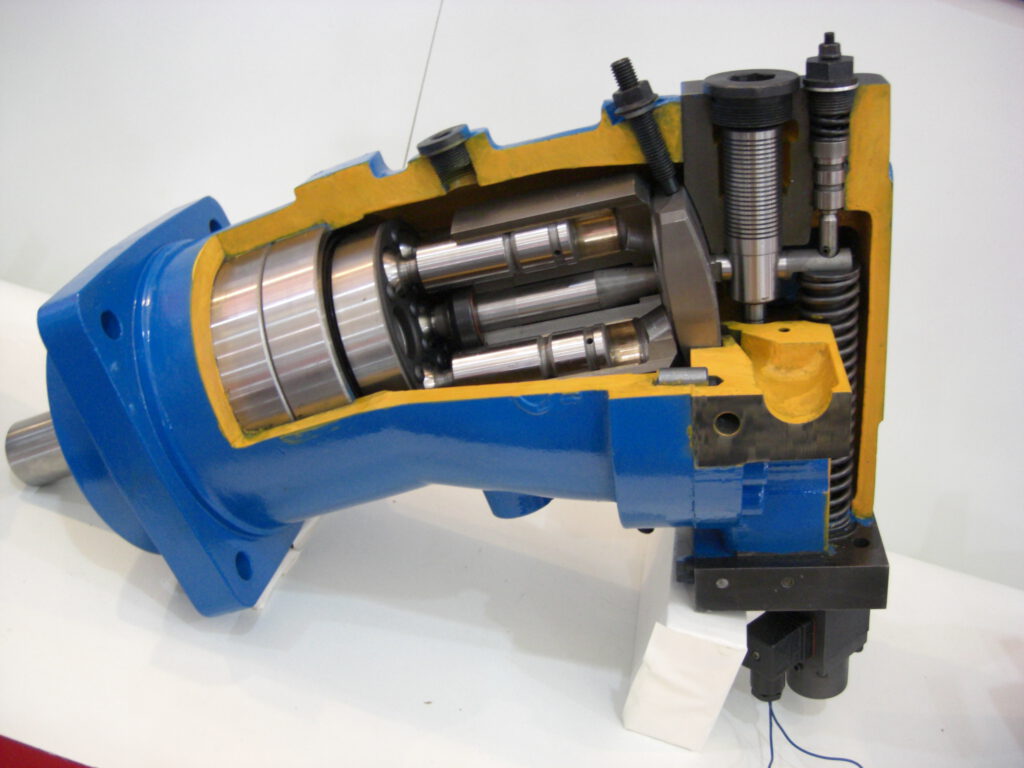

Hydraulic pumps

Pumps for converting mechanical energy into kinetic energy and pressure energy.

In this process, fluid is absorbed by the principle of rotation and made to flow with the help of pressure.

Types of hydraulic pumps:

- Gear pump

- vane pump

- piston pump

- Axial piston

- Radial piston

Hydraulic motors

Hydraulic motors convert pressure energy provided by the hydraulic pump into mechanical energy. In this process, the pressure energy (input) is transferred to the drive shaft via the fluid. This creates a torque and a speed (output). These parameters of the output result in the power of the motor.

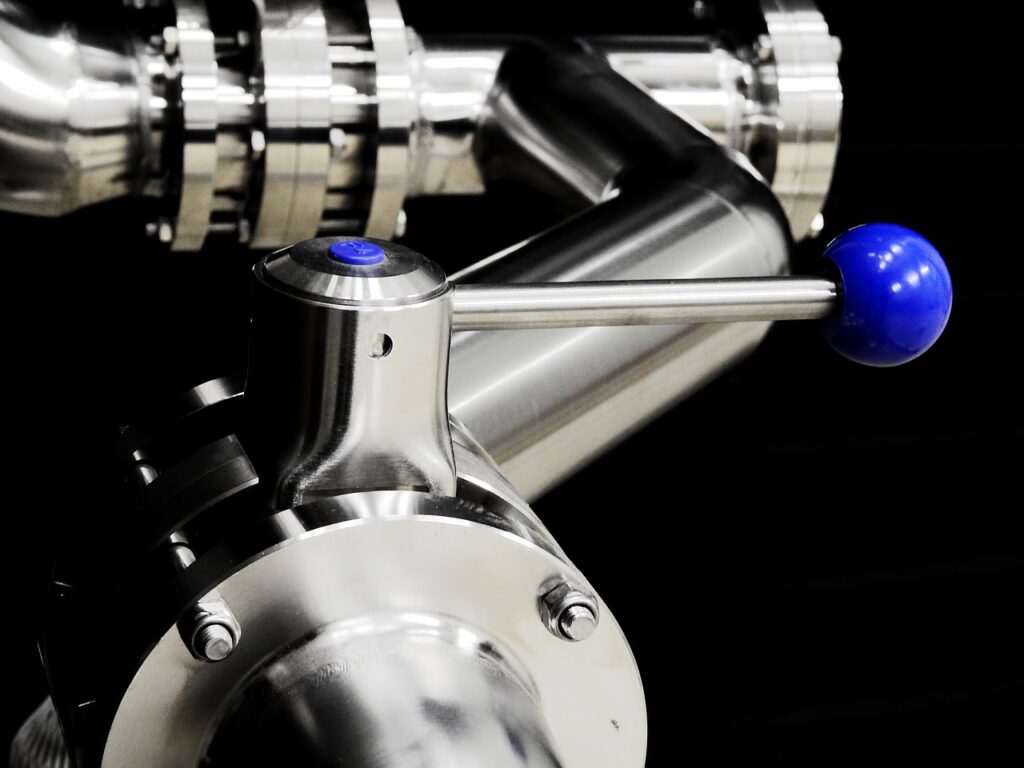

Valves

Valves regulate the direction of flow and the flow rate of the medium and are used for control purposes. The valve piston can be controlled directly, e.g. by a solenoid coil (directly controlled valve)

In the case of an indirectly controlled valve (pilot-controlled valve), the valve piston is controlled, for example, by a compressed air control connection via a pushbutton. This results in more components, which can lead to a higher susceptibility of the system. The main advantage to the directly controlled valve is the significantly lower force required to trigger it.

Types of valves:

- Directional valves

- Proportional and servo valves

- pressure valve

- flow control valve

- Stop valve

Filters and filter elements

A complete filter includes the housing and the filter element, which is placed in the housing.

Oil that has passed through the system is introduced through an inlet port on the housing. Inside the housing, it meets the filter element there and is pressed through the filter element to the clean side. In the process, foreign bodies and other impurities get caught in the meshes of the filter. Thus, the oil is cleaned of undissolved foreign matter larger than (or equal to) the mesh size. The main advantages resulting from this are the prevention of malfunctions (e.g. due to clogging) and the increase of the service life of your system or equipment.

Hydraulic power units

Hydraulic power units convert electrical (electric motor) or chemical (internal combustion engine) energy into hydraulic power. A simple hydraulic power unit usually consists of a pump, a motor, an accumulator and the hydraulic control system. Functioning as a drive system, the hydraulic power unit is also called an incomplete machine.

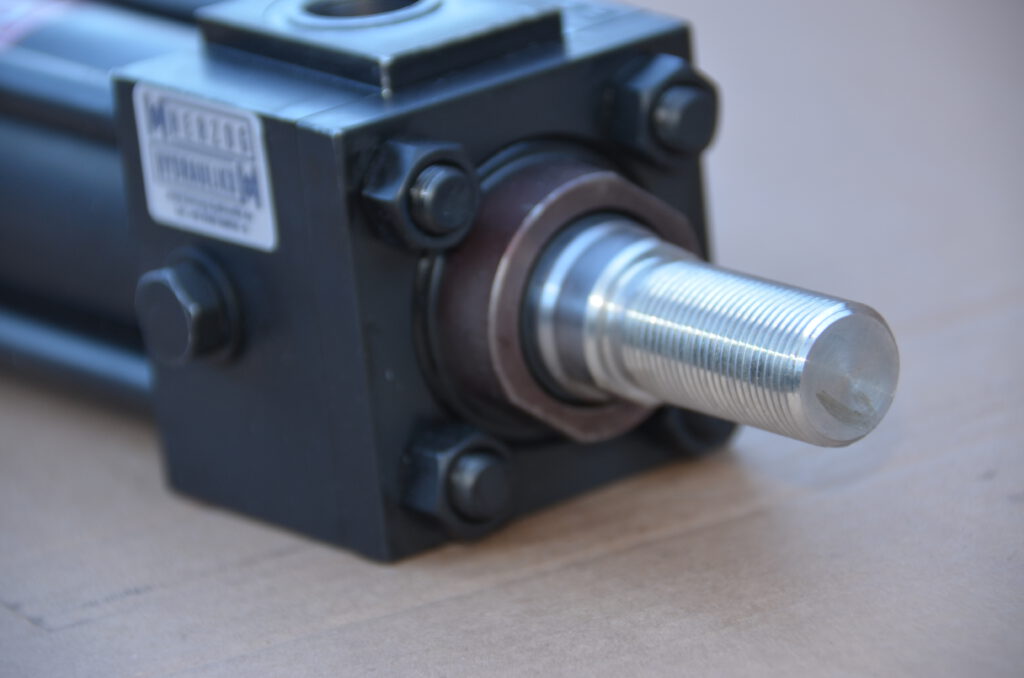

Hydraulic cylinders

Hydraulic cylinders are indispensable in hydraulic systems. They convert hydraulic energy, which is transmitted via the medium, into a force, i.e. mechanical energy. This is linear and easily controllable.

Common processes:

- Lifting

- Lowering

- Locking

- Moving

Hydraulic accumulators

Hydraulic accumulators are used to store a fluid under pressure. When required, the pressure is discharged. The resulting force is used to drive a subsequent process, such as lifting a weight or compressing another medium

Types of hydraulic accumulators:

- Diaphragm accumulators

- bladder accumulator

- Piston accumulator

- Spring accumulator

- Metal bellows accumulator Maintenance-free

- Air vessel